For the second last assignment, we were randomly put into groups of two in order to combine our concepts into one hybrid object for 3D printing. We have been asked to select three of each of our ideas and evaluate them based on the following criteria: function, form, self-supporting, and 3D printability. Then, we need to brainstorm a hybrid of two of our designs (one from each of us) and sketch concepts on paper. The next step is to model it using any of the software platforms we have explored, e.g. Rhino and Meshmixer. Lastly, we will be able to print our object on a Fused Deposition Modeling (FDM) printer.

|

| Preliminary sketches. |

Most of our designs were abstract in the sense of function and form. We obviously picked the ones we thought were self-supporting, i.e. able to print without support material. We also picked ones that had less extreme angles and shelf-like structures so the likelihood for success in printing is greater. Since we were encouraged to manipulate our objects and go beyond just placing the two objects together, we adjusted some of our designs to increase said likelihood, e.g. beveled the horizontal to the vertical surfaces.

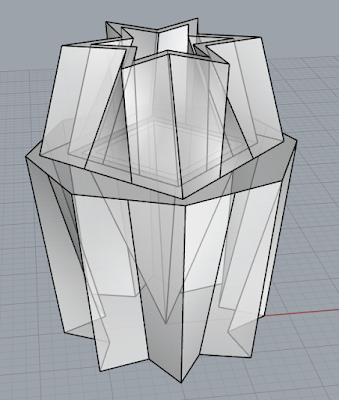

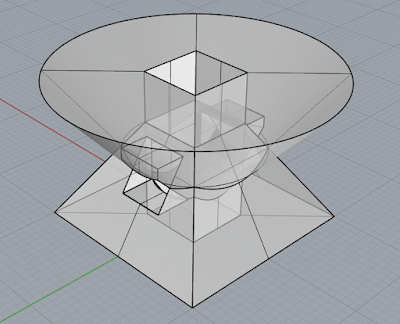

We decided to combine my ninth concept with Sarah's tenth design. We liked the dangerous, fantasy look and it can function as a vessel, weapon, crown, or an orb holder. We called our creation a "corb". Sarah's object has been repeated and placed on the pillars of my model in Rhino. The bottom surface of mine had been removed by accident and we figured to keep it as the hollowed out parts looked interesting.

|

| My concept. |

|

| Sarah's concept. |

|

| Combined and rendered in Rhino. |

|

| Top view. |

|

| Side view. |

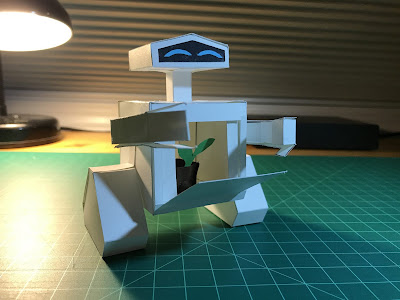

After using Rhino, we wanted to smooth out some of the edges and where our objects join. We did this in Meshmixer with the "RobustSmooth Brush" tool.

|

| Sculpted in Meshmixer. |

Before we can print our object, we have to open the file in Slic3r to set the print settings. We had to make sure the correct filament was selected, in this case, we are using "Generic PLA" which is a corn starch based biodegradable plastic. We also wanted the fill density to be at 0% so that our object will be hollow in order to save material. After all the proper settings have been applied, we exported the G-code file to a SD card and we were finally ready to print our object.

|

| Printing has just begun. This is one of several 3D printers we have at ACAD. |

This FDM printer was fairly easy to use, we were supposed to load our preferred colour of PLA filament and have the printer preheat as well as calibrate. Then, we just let it do its thing, printing layer by layer. It was a long process and the printer took over five hours to finish, but we are very proud and satisfied with the end product.

|

| Top view. |

|

| Bottom up. |

|

| Sarah planning to do something sinister with our new creation. |

I showed photos of our object to my friends and almost all of them said it looked like a bunch of butt plugs. I can assure you that was not our intention, butt you can use it however you like.

This has been a very enjoyable and memorable experience. We have encountered some challenges such as coming up with hybrid designs without putting things on top of each other, remembering how to use Meshmixer, and exporting other file types instead of the G-code. We also had to reprint our model as Sarah accidentally broke it. All in all, I gained some valuable knowledge through this group project and I hope to have more opportunities experimenting with 3D printing in the future.